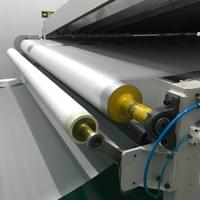

A professional PVB film manufacturer

HUATESHENG PVB

Product

Our PVB film uses good quality raw material, produced by advanced equipment and with a complete test before packing. It has ultra-high transparence and excellent flatness with a good rate of finished product and stable performance in processing.

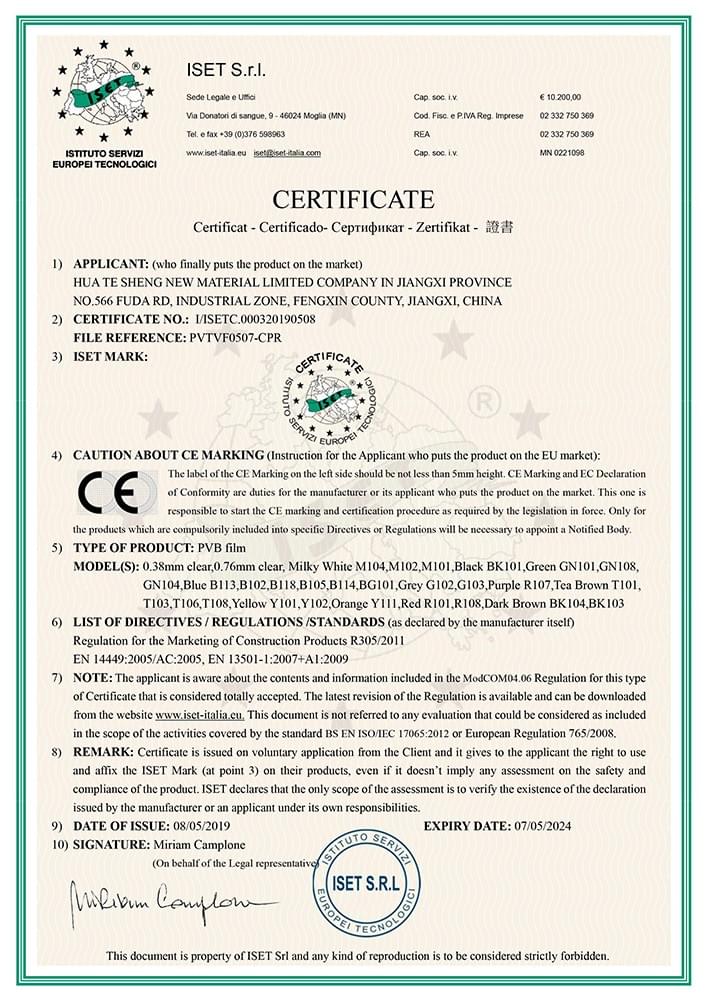

Authentication

ISO 9001

CE Certificate

Glass safe test

PVB Film Applications

1Glass Preparation

Cutting glass precisely and cutting tolerance must less then 2mm to avoid bubbles. Polish the glass edges and wash glass with softened water, then dry the glass and put into the laminating room.

2Lamination

The laminating room should be clear and dust-free, and operator should wear neatly. Room temperature should be 15-25°C and the humidity 18-40%. Full prelaminating process as following:

a. Lay one piece of clean glass on table.

b. Place the PVB film on the glass, the edge of cutting PVB film should 2- 5mm more than the edges of glass. Do not touch the glass when cutting PVB film.

c. Lay another piece of clean glass on PVB film.3Pre-pressure Exhaust

In order to get well sealed edge, the air between the film and the glass needs to be pressed out. As normal, there are two methods below:

a. Rolling De-airing

The pre-laminated glass to heat up to 25-40°C on glass surface and put it into the first roll by the space of roll is 1mm less than the thickness of laminated glass with pressure in 0.2-0.5 MPa. And also enter into thermostatic container to heat up to 60-80°C. Then through the second roll by the space of roll is 2mm less than the thickness of laminated glass with pressure in 0.3-0.5 MPa. After finishing to second roll, seal the four sides of laminated glass with clear tape to avoid bubbles.

b. Vacuum De-airing

Put the pre-laminated glass into a vacuum bag or vacuum rubber gasket, then use the cool or heat pumping to expel the air. Recommend: the decompression vacuum degree is exceed 650 mmHg. For the cool pumping temperature should be lower than 25°C and keep it for 30-40 mins; while in the period of heat pumping, the temperature should be 70-120°C and keep it for 30-60 mins.4In Autoclave

Put laminated glasses into autoclave and note the space of two pieces of laminated glass is exceed 5mm. Then sealing the autoclave door to raise the autoclave temperature up to 80°C and then raising rate in 5°C per minute after temperature 80°C , and also the pressure in 0.06MPa per minute. When it up to 120-140°C and 1.0-1.5MPa, keep the temperature and pressure for 30-60 minutes. After that, keep the pressure and lower the temperature to 80°C,at the same time,loose the pressure to the atmosphere pressure. Finishing the high pressure molding process, we can have the final laminated glass for usage.

Packaging & Transportation

PACKAGING

Each layer of PVB film is separated by PE film, and vacuumed in aluminum foil bag, then put into plywood box.

STORAGE

Should stored in clean warehouse under the ordinary temperature. No direct sunlight. When vacuumed package is opened, it should be stored in the place with the temperature 15℃-25℃, humidity of 20%-40%.

TRANSPORTATION

Avoid direct sunlight, rain and strong shake during the transportation.

Avantage Of Use PVB Film

Polyvinyl butyral(PVB) film is made from PVB resin and used as an interlayer to produce laminated glass. If the laminated glass is broken, it holds the fragments together, avoiding a disintegration leading to injury of persons. Hence laminated glass is also called safety glass. PVB interlayer is the best laminating film, it has good adhesive properties, and can maintain its strength under sunlight. With it’s elastic material PVB film can resist impact and provide sound insulation.

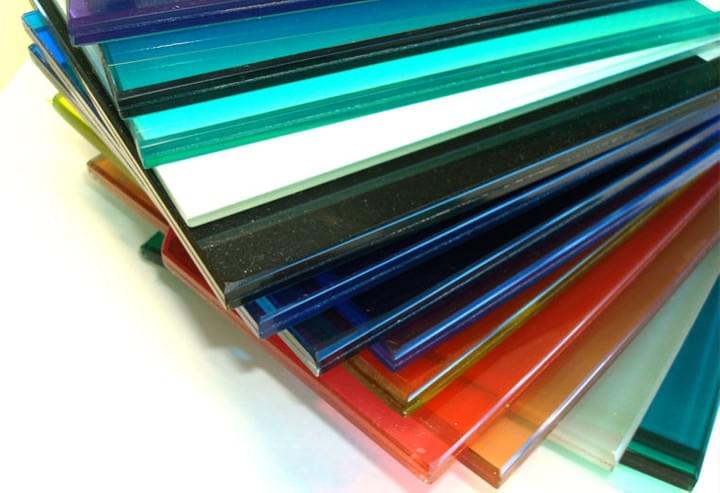

PVB film is used in outer wall glass, especial for rise buildings. It is recognized for it’s functions of safety, sound insulation, and thermal insulation. PVB film has a high level of performance in transmission of light. Clear PVB film is the most commonly used, but color PVB film is often used in construction sites also because of it’s aesthetic qualities. Regular thicknesses of 0.38mm, 0. 76mm, 1.14mm and 1.52mm are available and other customized requirement can be met.

PVB film is widely used in automobile windshields due to it’s safety and is now often used for other windows to reduce noise. Clear and light blue light green PVB layer can be use for windshields also, some time as a color band on the top. Regular thicknesses of 0.45mm 0.6mm 0.76mm are available and other customized requirement can be met.

Cooperation

Sample & price

Free samples are available to laminated glass factories.

Please contact our sales for detail prices as following:

Betty

Mobile/Whatsapp/Wechat: +86 17187876390

Email: [email protected]

Agent

To expand overseas market, we are looking to increase our worldwide agents, especially as exclusive agents in a region or country.

If you are interested in, please do not hesitate to contact us.- Send Me Massage -

About Us

We are a professional PVB film manufacturer in China. We produce PVB film with good quality fresh resin.

Contact Us

Carl

Mobile/Whatsapp/Wechat:

0086 17187876390

E-mail: yufengxin@

Copyright © 2022 Huatesheng All Rights Reserved.